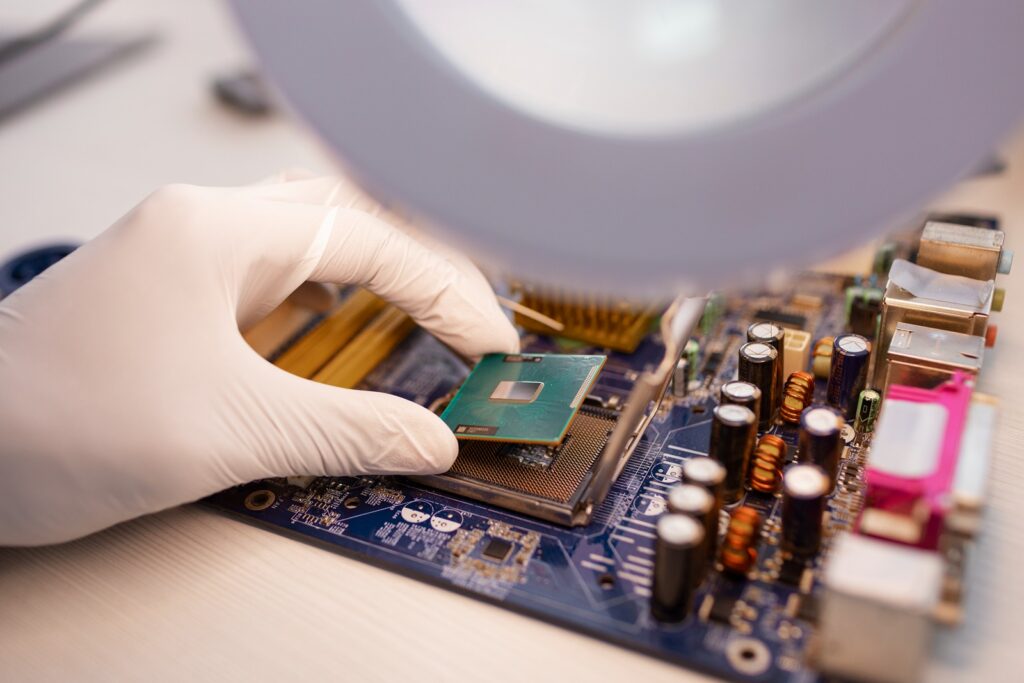

State-of-the-Art High-performance assembly

Industrial & Electronic engineering staff on-site

Detailed Part Tracking

Sigma has invested in an inventory tracking system that goes beyond the standard component lot traceability. It provides serialization of components to the packaging level. Every reel can be traced and controlled. All material is continually cycle counted for on-hand quantity accuracy.

In addition to individual packaging identification Sigma’s inventory system can track characteristics unique to LEDs such as flux, voltage and color binning.

Part Control

Sigma’s inventory control system can also allocate and quarantine common component material to a specific order. Making it easy to track customer provided raw material.

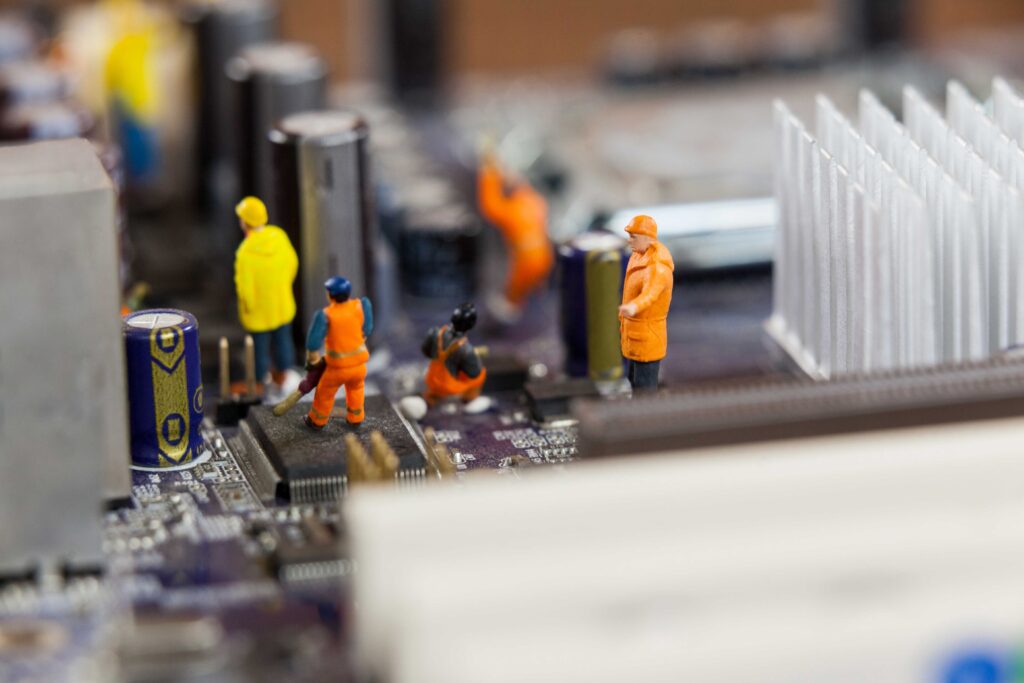

Functional Test Fixture Design

Sigma’s engineering team understands designing for manufacturability and how important final testing is to the assembly process.

At the very beginning of the design process the engineering team is thinking about how to optimize testing and programming to minimize the production time and maintain high quality.